Server at a depth of 35 meters

In 2020, Microsoft announced the success of one project, namely the test of a data center that worked in the ocean at a depth of 35 meters. The server was placed in a large capsule, which was then submerged under water.

What was it for?

Many people know that when working in a separate room, the equipment gets very hot, so a high-quality and expensive air conditioning system is needed.

But in this case we are talking about natural cooling. But there is another plus here, since you can place the centers closer to the user, so this greatly reduces the time to process the request. Statistics show that about half of the population lives within 100 kilometers of the coastline. And you can build such projects in just 3 months.

But there is also a minus, in the usual mode it is almost impossible to serve projects. So there is a lot of attention paid to reliability issues.

What is this project?

The first tests of this kind of capsules were carried out back in 2015. This is the first phase of a new project, the goal of which was that the data center could work just like that.

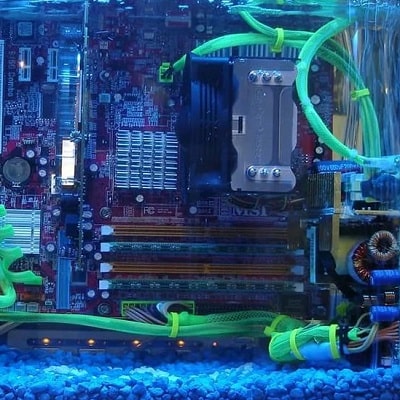

Next, the team had to confirm that commercial scaling of this technology was truly feasible and that such systems could operate steadily under real-world conditions. In the spring of 2018, the capsule was submerged under water to a depth of 35 meters, where it was exposed to long-term environmental influences such as pressure fluctuations and temperature changes. After installation, specialists carried out an extensive series of reliability and performance tests aimed at assessing how the equipment would behave in isolation from external physical factors and human intervention. The capsule housed 864 servers, and the engineers monitored their work continuously, analysing stability, energy efficiency, and the overall capability of the infrastructure to support large-scale data operations.

Initially, it was assumed that the work would be as productive and stable as possible. On land, you immediately need to take into account temperature changes and the human factor, oxygen, humidity and other parameters. And the company data showed that the volume of failures was 1/8 of similar centers operating on land. The thing is that the capsule was filled with nitrogen and was airtight. That is, this is the minimum impact on the equipment.